Formwork, the backbone of concrete construction, shapes and supports fresh concrete. Full ties and nominal ties, crucial elements in this process, anchor the formwork securely. These specialized materials ensure proper pouring and curing, maintaining structural integrity. Without them, the formwork could shift or collapse, compromising safety and quality. As concrete hardens, these ties work tirelessly, holding everything in place. Their importance cannot be overstated in creating strong, durable structures that stand the test of time. Builders rely on these simple yet effective tools to bring architectural visions to life, one pour at a time.

Full ties, nominal ties, and aluminum wall ties play crucial roles in concrete construction. These essential components serve distinct purposes, impacting structural integrity and safety. Understanding their uses and importance enables engineers to design robust, durable buildings. Let’s explore how these ties function and why they matter in modern construction practices.

What Are Full Ties?

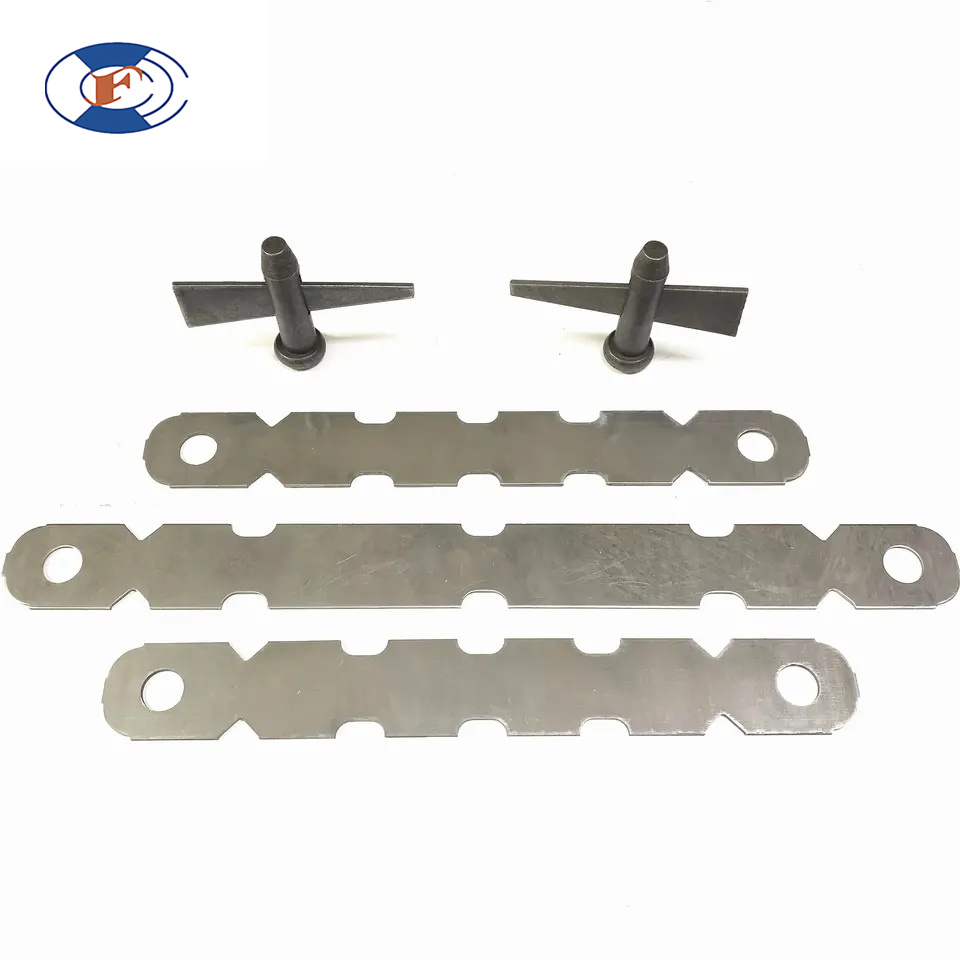

Full ties are strong connectors that hold formwork sides together. They pass through the concrete’s thickness, ensuring a continuous link. Typically, these ties are made of steel, known for its strength and durability.

Concrete’s immense pressure threatens formwork stability during pouring. Enter full ties: stalwart guardians against collapse. These robust supports brace mold walls, resisting concrete’s weighty push. Their steadfast grip maintains even distribution and proper shaping as the mixture solidifies, preserving structural integrity throughout the curing process.

Concrete hardens, rendering full ties obsolete. Removing them preserves aesthetics and structural soundness. Workers then fill the resulting holes, creating a flawless surface. This process ensures the finished product meets both visual and engineering standards, eliminating potential weak points or blemishes in the concrete structure.

Why Are Full Ties Important?

In massive concrete endeavors, full ties play a crucial role. Buildings, bridges, and hefty structures rely on these unsung heroes. They fortify formwork against the immense force of liquid concrete. Without their steadfast support, cracks could form, shapes could warp, or entire projects could crumble. These ties stand as silent guardians, ensuring the integrity of our most ambitious constructions.

Full ties are crucial. They strengthen and stabilize formwork, ensuring concrete sets correctly. Moreover, they keep workers safe by securing formwork during pouring. After curing, full ties also enhance the concrete structure’s strength.

What Are Nominal Ties?

Nominal ties are not meant to support as much pressure as full ties. They are used in smaller concrete projects with lighter loads. These ties keep the formwork sides together but don’t go through the entire concrete thickness.

Nominal ties are usually made of plastic or similar lightweight materials. This makes them easy to use. They’re often used in building sidewalks, small walls, or simple concrete structures. Although not as strong as full ties, nominal ties are crucial. They keep the formwork stable and prevent shifting during pouring.

After the concrete hardens, we leave nominal ties in place. They don’t affect the concrete’s strength or appearance. Some nominal ties are made to be embedded in the concrete. This design gives a smooth finish without needing removal.

When to Use Full Ties vs. Nominal Ties?

Concrete project size dictates tie selection. Full ties excel in large-scale builds like bridges, withstanding immense pressure during pours. Their robust design ensures formwork stability. Conversely, nominal ties suit smaller endeavors – sidewalks or garden walls. These lighter options suffice for low-load structures, offering easier handling. Cost-effective, they can remain embedded post-pour. Choose wisely based on project demands to achieve optimal results and structural integrity. Proper tie selection guarantees safe, efficient concrete work across various construction scales.

The Role of Aluminum Wall Ties in Concrete Construction

Aluminum wall ties have transformed construction in recent years. These lightweight yet robust connectors resist corrosion, offering superior performance as formwork ties. Their strength and durability make aluminum an ideal material choice, revolutionizing building techniques across the industry.

Aluminum wall ties, like full and nominal ties, serve to connect the two sides of the formwork. However, they offer several advantages over traditional steel ties. Aluminum ties are lighter, easier to handle, and resist rust and corrosion. Thus, they are better for moist or chemical-prone environments than steel ties.

Aluminum wall ties offer significant environmental benefits. They’re recyclable, allowing reuse in future projects. Thus, they provide an eco-friendly choice for construction companies aiming to lower their environmental impact.

For more on aluminum wall ties and their benefits in concrete work, visit aluminum wall ties.

How Full Ties and Nominal Ties Impact Concrete Quality

Both full ties and nominal ties are important for ensuring that the concrete sets correctly and the formwork stays intact. However, their impact on the final quality of the concrete structure depends on how they are used.

Full ties excel at supporting formwork, ensuring smooth concrete setting and a flawless finish. They maintain structural integrity when used correctly. Nominal ties, while suitable for smaller projects, offer less support. Improper use or insufficient support can lead to formwork shifts, uneven concrete, or structural cracks. Choosing the right tie type is crucial for project success and long-term durability.

Final Thoughts

Concrete projects demand specific tie types based on scale and load. Full ties provide crucial support for large-scale builds, resisting intense pressure from poured concrete. Smaller structures with lower loads can rely on nominal ties. Both varieties secure formwork throughout pouring and curing, yielding robust, long-lasting results. The choice between full and nominal ties hinges on project size and structural demands, ensuring optimal strength and stability in every concrete construction.

Concrete structure size and load dictate tie selection. Proper ties stabilize formwork and ensure correct concrete setting. Choose wisely for a top-notch finished product. The right ties guarantee formwork stability, leading to superior concrete results. Careful selection based on project specifics yields high-quality outcomes.

Discover how aluminum wall ties boost construction quality and efficiency. These innovative components enhance project outcomes. Explore their advantages to elevate your building process. Learn more about these versatile tools and unlock their potential for your next venture.